Drying technology

Practical Action

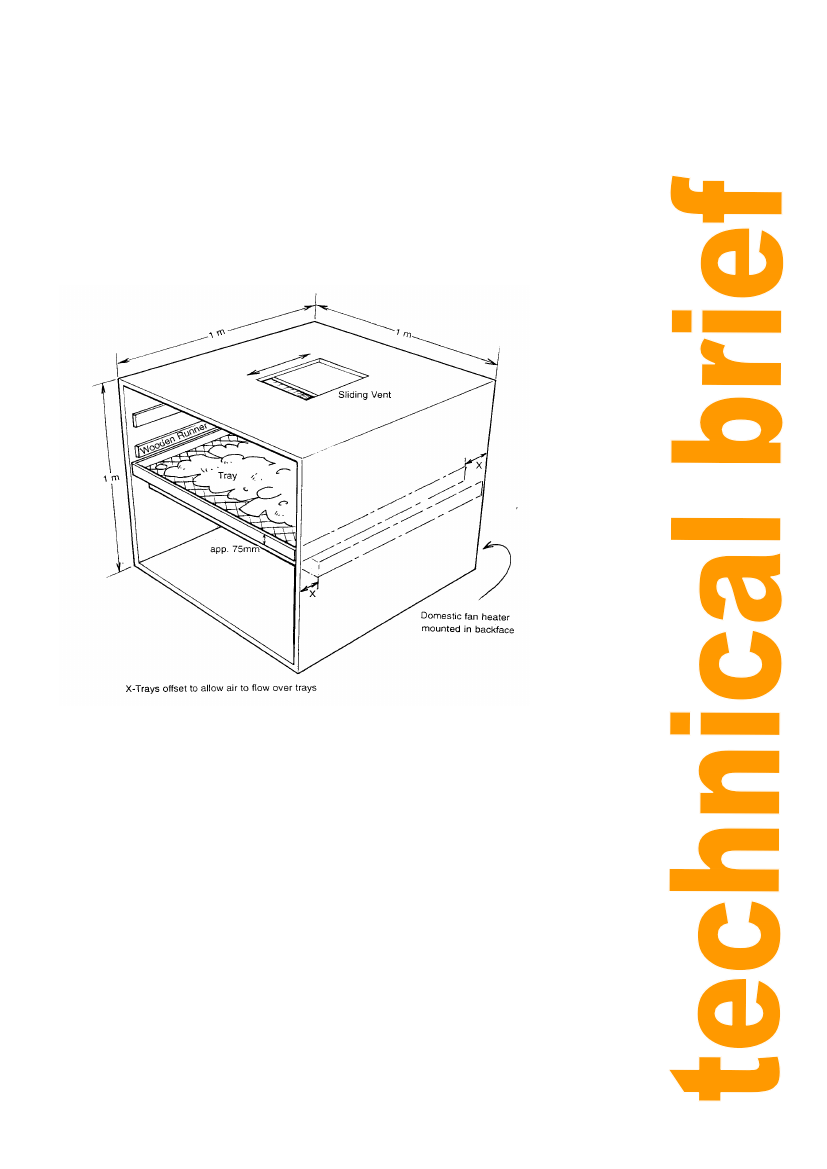

Small Electric Dryers, as shown in Figure 5, can be constructed at a cost equal to or less than

the solar dryers described above. Typically, such a dryer consists of a plywood box one metre

cube, with a door to the front. Between 6 and 10 mesh trays are supported on wooden runners on

the dryer walls. Heated air is supplied by a domestic 2kw fan heater to the rear base wall. The

heater should be re-wired with an external thermostat (placed in the drying chamber) so that the

heater elements are controlled by the thermostat while the fan runs all the time. This is a simple

job that can be carried out by a competent electrician. The air exits via an opening at the top of

the rear wall. The trays should be arranged so as to cause the air to follow a zig-zag path as it

passes through the dryer as shown in Figure 5.

Figure 5: Small electric dryer. The air should follow a zigzag path.

Provided sufficient value is added by drying to cover electricity costs, such dryers offer distinct

advantages over solar dryers which include:

greater daily output

higher drying temperatures and thus considerably more rapid drying

faster drying due to the forced air flow

total independence from weather conditions

good control of the drying process.

4